Home

Backwards maneuvering truck/trailer combinations can be challenging, especially if the vehicle combination has more than one articulation. Logistics companies experience significant costs due to damage caused by vehicle combinations that are in the process of ‘docking’: parking the vehicle backwards to a dock door for loading and unloading.

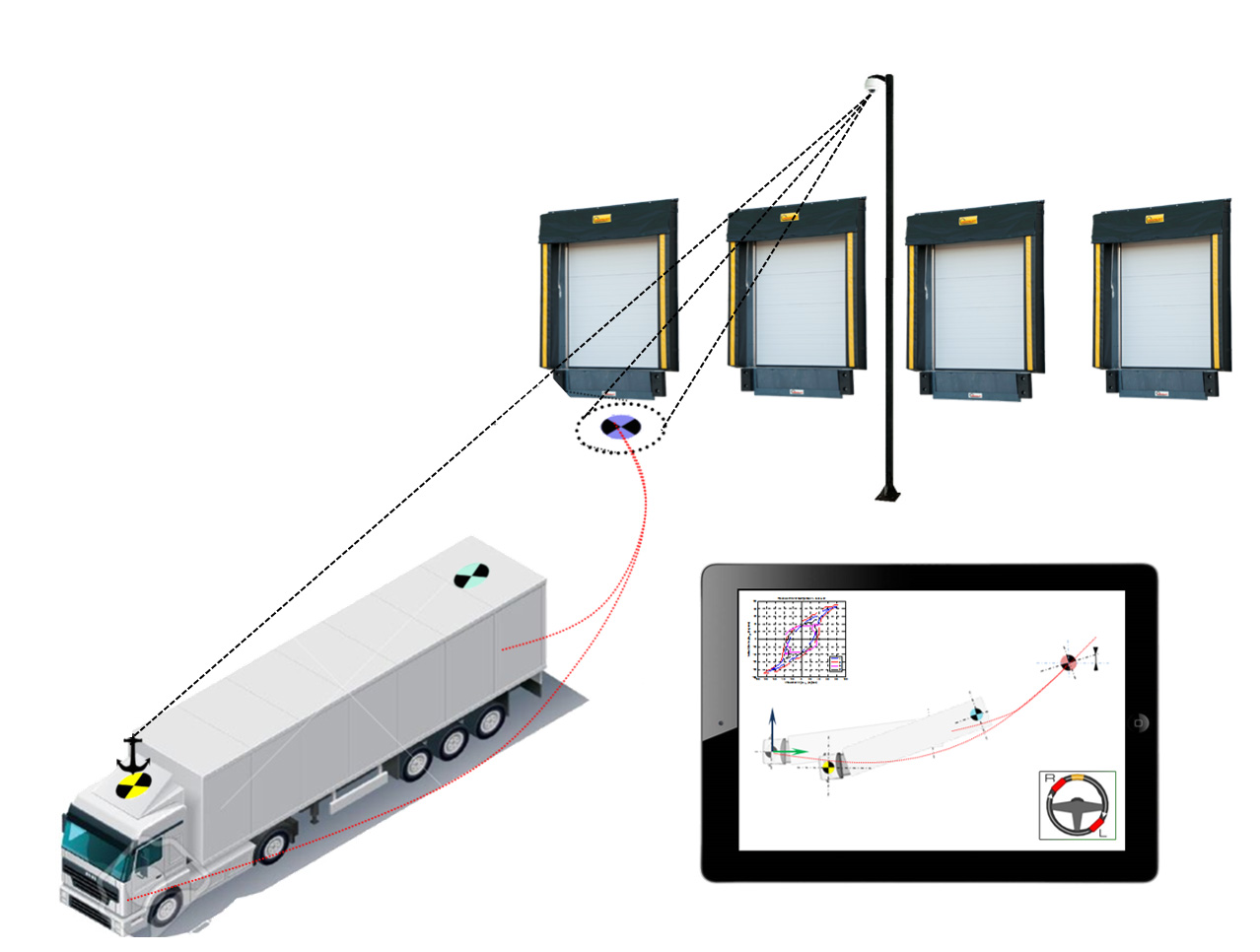

VISTA stands for VIsion Supported Truck docking Assistant. The aim of VISTA is to develop a system that supports truck drivers while maneuvering their vehicle combinations on logistics areas towards dock doors. The heart of the VISTA solution consists of camera based, accurate localization of truck and trailer(s). The cameras are mounted on the distribution centre. Based on this localization, an optimal, feasible path is calculated by the system and the driver then gets information on how to follow this path by means of an intuitive user interface. This user interface is handed over to the driver while entering the distribution center.

For VISTA, no instrumentation in the truck is necessary. Hence, the solution can be made available for all existing trucks. By using camera technology and by integrating the system in existing processes on distribution centers, the VISTA solution is low on CAPEX and OPEX.

VISTA aims for demonstrating the solution on a Technology Readiness Level (TRL) 7. This means that the solution will be demonstrated in real life in a complex, practical environment. Upon successful demonstration, commercial parties will bring the solution to the market.

VISTA is an Interreg V-A project, co-financed by the European Union via the INTERREG Deutschland-Nederland programme, the Miniserium für Wirtschaft, Innovation, Digitalisierung und Energie of Nordrhein-Westfalen and the Province of Gelderland. The project has a budget of 2.1 M€ and covers the period January 2019 – June 2023. VISTA partners are: Bricklog Deutschland GmbH & Co KG, Coduct GmbH, HAN (Hogeschool van Arnhem en Nijmegen), Hochschule Rhein-Waal, intoEU, ICR3ATE Digital Makers Lab B.V., Track32, V-Tron GmbH and various logistics forwarders and distribution center owners.